Ceramic permeable bricks are a type of outdoor paving material that rivals the texture of natural stone while offering the added benefit of water permeability. These bricks are primarily made from recycled ceramic materials, supplemented with other mineral additives, and formed under high pressure through a special manufacturing process. Following this, they are subjected to a prolonged period of high-temperature firing. This innovative production method not only leverages waste materials for environmental sustainability but also results in a durable and aesthetically pleasing surface that facilitates groundwater recharge by allowing rainwater to filter through.

What are Ceramic Permeable Bricks?

Ceramic permeable bricks, also known as ceramic pervious bricks or porous ceramic bricks, are a type of eco-friendly building material designed to allow water to pass through their surface to the ground beneath. These bricks are made from a mixture of natural materials such as clay, shale, and other recyclable materials that are fired at high temperatures to create a hard and durable surface with porous properties. The main characteristic of ceramic pervious brick is their ability to facilitate the natural absorption of rainwater and reduce runoff, thus helping to replenish groundwater supplies and mitigate flooding in urban areas. They are commonly used in sidewalks, plazas, driveways, and other outdoor areas where water drainage and environmental sustainability are concerns. Ceramic permeable bricks not only contribute to urban drainage and flood control but also promote the ecological balance by allowing water to filter through the ground, which helps to cool urban areas and reduce the heat island effect.

Eco-Friendly Ceramic Permeable Bricks vs. Conventional Plaza Bricks

Eco-Friendly Ceramic Permeable Bricks offer significant environmental advantages. They lower the surrounding temperature and restore the natural water storage capacity to prevent groundwater depletion. These bricks enhance the survival conditions for vegetation, regulate atmospheric humidity, purify the air, and revitalize the ground's water cycle system.

In contrast, Conventional Plaza Bricks contribute to the considerable loss of surface water, leading to waterlogging and urban flooding. They maintain high surface temperatures for extended periods, block the natural absorption of water by the earth, and contribute to the urban heat island effect, making cities significantly warmer.

“…Sponge Cities: Enhancing Urban Resilience Through Permeable Pavement…”

Sponge cities utilize urban green spaces, roads, and water systems to absorb, store, and slowly release rainwater, effectively alleviating urban waterlogging, reducing runoff pollution, conserving water resources, and protecting and improving the urban ecological environment. The Chinese standard GB/T 50378 "Green Building Evaluation Standard" stipulates that achieving a permeable pavement area ratio of 50% in hard-paved surfaces earns three points, highlighting the increasing governmental support for policies promoting permeable bricks usage. With the national push towards sponge city construction, the importance of building sponge cities is gaining recognition. A key feature of sponge cities is the creation of a "sponge" through road permeable paving, where ceramic pervious bricks stand out for their functionality, performance, raw materials, and socio-economic benefits, making them unparalleled and irreplaceable compared to other paving materials.

Proudly Made in China: Your Trusted Chinese Manufacturer and Supplier

Ceramic Permeable Bricks: Revolutionizing Urban Paving

High Permeability

Engineered with specialized inorganic materials, these bricks excel in water permeability, effectively managing heavy rainfall and enhancing groundwater recharge.

Water Retention

Capable of storing substantial rainwater, they reduce urban runoff and mitigate flooding, while their porous structure supports natural evaporation to cool and humidify urban spaces.

Recyclable

Their unique design allows for repeated reuse, offering an eco-friendly solution to urban construction and reducing environmental impact.

Durability

Exceptionally strong and resistant to compression, frost, and weathering, these bricks are ideal for durable and sustainable outdoor paving.

Customizable Ceramic Permeable Bricks: Diverse and Durable

Product Dimensions and Thickness:

Our ceramic porous Bricks come in a wide array of sizes, including 600x900, 300x900, 600x600, 300x600, 200x600, 150x600, 400x400, 422x200, 300x300, 200x200, 150x150, and 100x200 mm, with thickness options of 30mm, 40mm, 50mm, 55mm, 60mm, 70mm, and 80mm.

Color Range:

Available in a versatile palette of white, yellow, brown, red, light grey, and dark grey.

Customization:

We offer complete customization in styles, colors, sizes, and thickness to meet your specific requirements.

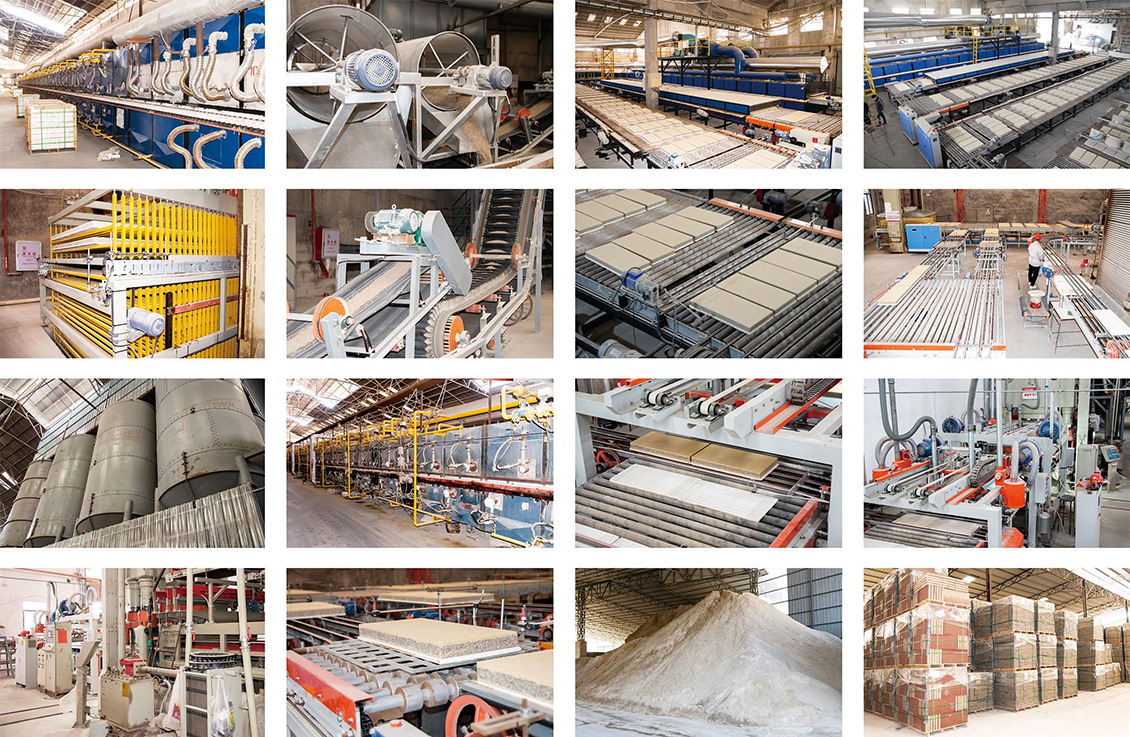

Manufacturing Excellence: Our factory produces high-quality bricks characterized by color customization, high wear resistance, permeability, anti-slip properties, and clog resistance, with simple maintenance needs.

Application Scenarios: Ideal for municipal streets, residential roads, park walkways, commercial plazas, and light parking lots.

Key Advantages: Our bricks boast a delicate surface, clear texture, stone-like feel, micro-pore clog resistance, and are easy to clean.

Durability: Designed to last over 30 years, with maintenance as simple as washing with a high-pressure water jet.

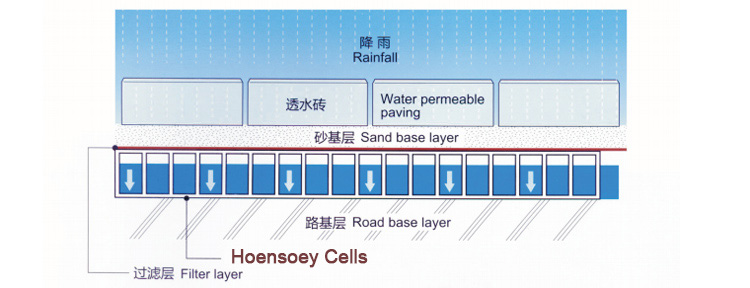

Hoensoey Cells and Permeable Ceramic Bricks: The Perfect Stormwater Management and Pavement Enhancement Solution

The combination of Hoensoey Cells and permeable ceramic bricks offers an efficient and aesthetically pleasing urban stormwater management and pavement improvement solution. Hoensoey Cells' modular design optimizes the collection and infiltration of rainwater, effectively reducing waterlogging and sewage discharge issues. Meanwhile, permeable ceramic bricks not only enhance the ground's permeability but also beautify the urban landscape with their rich colors and textures.

This innovative pairing promotes groundwater recharge while protecting the pavement from water erosion damage, extending its lifespan, and significantly enhancing the city's overall appearance. In summary, the collaborative use of Hoensoey Cells and permeable ceramic bricks provides an ideal solution for efficient stormwater management and pavement beautification, offering both environmental and practical benefits.

Eight Functions of Technological Eco-Friendly Ceramic Permeable Bricks

Excellent Water Permeability

"Natural precipitation can quickly penetrate the surface, timely replenishing groundwater resources, thus storing water while alleviating urban waterlogging phenomena."

Strong Water Absorption

"Suitable for use on public or home kitchen and bathroom floors, it can instantly absorb surface water, providing excellent slip resistance."

High Compressive Strength

"Formed under high pressure and sintered at high temperatures, its compressive and flexural strength surpass other flooring materials."

Low-Carbon and Environmentally Friendly

"With a long product life and resistance to weathering, it can be recycled and reused indefinitely."

Automatic Regulation

"Its outstanding permeability and breathability can regulate the temperature and humidity of the ground surface, eliminating the 'heat island effect' and maintaining ecological balance."

Safety and Comfort

"Road surfaces remain free of water accumulation during rainy days, preventing nighttime glare and enhancing the safety and comfort of vehicle and pedestrian traffic."

Noise Reduction

"Its porous structure can absorb the noise generated by vehicle traffic, creating a quiet and comfortable transportation environment."

Crafting Sustainability: The Production Process of Ceramic Permeable Pavers

The production process of ceramic porous bricks involves several key stages, meticulously designed to create bricks that are both durable and capable of allowing water to pass through them. Here's an overview of the process in English:

1. Material Selection and Preparation:

The process begins with the selection of raw materials, typically including various types of clay, recycled ceramics, and sometimes industrial waste products. These materials are crushed into a fine powder and thoroughly mixed to ensure uniformity.

2. Forming:

The mixed material is then moistened and formed into the desired shape of the bricks. This can be achieved through extrusion or pressing, where the material is either forced through a mold or pressed into molds to form the bricks.

3. Drying:

After shaping, the bricks are left to dry. This can be done either naturally, by leaving the bricks out to air dry, or more commonly, in a controlled drying chamber where humidity and temperature are carefully regulated to ensure uniform drying without cracking.

4. Creating Porosity:

To make the bricks permeable, porosity is introduced. This can be achieved by adding materials that will burn off during firing (like sawdust or rice husks), leaving behind tiny pores, or through the creation of air pockets within the brick during the forming process.

5. Firing:

Once dry, the bricks are fired in a kiln at high temperatures, typically between 1000°C and 1200°C. The firing process vitrifies the clay, making the brick strong and durable. The materials added to create porosity burn away, leaving the brick with its characteristic permeable structure.

6. Quality Control:

After cooling, each brick is inspected for quality. Parameters such as size, shape, strength, and permeability are checked to ensure they meet the required standards.

7. Packaging and Shipping:

Finally, the finished bricks are packaged and prepared for shipping to construction sites, ready for use in a variety of applications from driveways and pathways to larger urban and green space projects.

This process highlights the blend of traditional ceramic production techniques with innovative methods to create a product that is both eco-friendly and functional, offering a sustainable solution for modern construction challenges.

Partner with Us for a Greener Future in Construction

Ready to revolutionize your outdoor space with our eco-friendly and durable Ceramic Permeable Bricks? Don’t miss out on the opportunity to enhance the sustainability and aesthetics of your projects. Contact us today to discover the perfect solution for your needs, and let's pave the way to a greener future together. Your journey towards an innovative and environmentally conscious landscape starts here!

roger@hoensoey.com +86 18016678377 (Whatsapp)

Send a Message

Explore the Versatility of Our Ceramic Permeable Bricks:

Features, Applications, Technical Specs, and Environmental Benefits

- Eco-friendly permeable bricks

- Durable ceramic pavers

- Water-permeable ceramic tiles

- High-strength pervious bricks

- Sustainable drainage solutions

- Urban flood prevention bricks

- Rainwater harvesting pavers

- Low carbon footprint materials

- Residential driveway permeable pavers

- Urban landscape ceramic solutions

- Permeable pavement for parks

- Garden walkway tiles

- Eco-friendly parking solutions

- Water management in construction

- Sustainable building materials

- Green infrastructure components

- High porosity ceramic bricks

- Weather-resistant ceramic tiles

- Freeze-thaw durable pavers

- Easy-installation permeable bricks

- Low maintenance paving solutions

- Slip-resistant outdoor tiles

- Heavy load-bearing pavers

- Innovative drainage technology

- Groundwater recharge pavers

- Heat island reduction tiles

- Permeable surfaces for wildlife

- Pollution filtering permeable pavers

- CO2 reducing building materials

- Rain garden compatible bricks

- Stormwater management solutions

- Biodiversity-friendly landscaping materials

Proudly Made in China: Your Trusted Chinese Manufacturer and Supplier